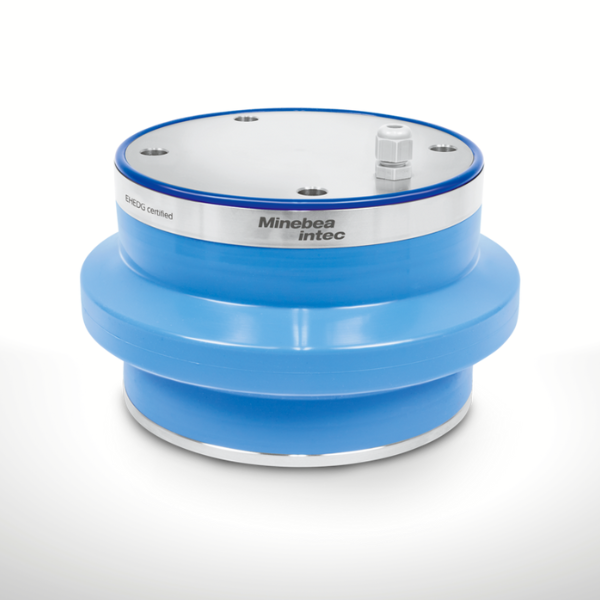

Choosing loadcells for silo, vessel and tank solutions

The right loadcells for Silo, Vessel and Tank systems are critical in ensuring accurate and consistent measurements for a variety of industries including food and beverage, pharmaceuticals, chemical and many others.

These load cells provide accurate and consistent measurements of stored materials, allowing for better management of inventory and improved process control. With their reliability, durability and ease of use, these load cells are a key component in many industrial applications.